Development Trends of Fluidized Bed Granulators

Fluidized bed granulation equipment is currently widely used in pharmaceutical production processes, with significant advantages. This method combines mixing, granulation, drying, and even coating operations in a fully enclosed container. Compared with other wet processes, it has the characteristics of simple process, short operation time, and low labor intensity. At present, fluidized bed granulation technology is being increasingly widely used, and the gap between domestic and international production of fluidized bed granulation machines is also becoming smaller. This technology is of great significance for the modernization of traditional Chinese medicine production in China. Starting from the principle of fluidized bed granulation, I will introduce the current and development trends of fluidized bed application.

1. Basic principle of fluidized bed

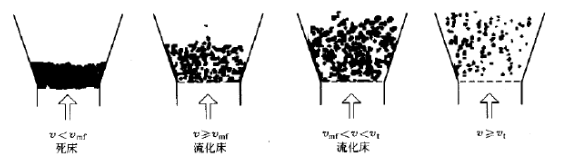

In the equipment, granular materials are stacked on distribution boards. When gas enters the bed layer from the lower part of the equipment and the airflow speed increases to a certain extent, solid particles produce a boiling state on the bed layer, which is called fluidization, and this bed layer also becomes a fluidized bed. Due to the different characteristics of solid particle materials and factors such as bed and airflow, there can be three states in the bed layer (as shown in the following figure):

Stage 1: Fixed bed stage: The wet material enters the dryer and first lands on the distribution plate. When the hot air flow speed is not enough to make it move, although the material particles come into contact with the airflow, the solid particles do not change their relative positions. This is called the fixed bed stage, and the fixed bed is the first stage of the fluidization process

The second stage: Sulfurization bed stage: When the airflow velocity further increases, it is enough to blow up the material particles, causing them to move freely in the airflow. The material particles collide and mix with each other, causing the bed height to rise, and the entire bed to present a liquid like flow state. When the particles are suspended (i.e. the bed span increases), the flow rate is increased, and the bed pressure drop remains unchanged, The reason is that the porosity between the particles of the material has increased, and the pressure drop of the fluid is only consumed to resist the weight of the particles, which is caused by lifting it up to prevent the bed height from decreasing. This indicates that the pressure drop in the bed layer is not related to the increase in flow rate, and is roughly equal to the actual weight of the bed layer per unit area, which is called the fluidized bed stage.

Stage 3: Airflow conveying stage

If the airflow velocity continues to increase on the basis of the above, when it exceeds point C, it indicates that the airflow velocity is greater than the settling velocity of solid particles. At this point, the bed height is greater than the container height, and solid particles are carried away by the airflow. The bed material decreases, the porosity increases, and the bed pressure decreases. When the flow rate increases to a certain value, the flow rate that makes the resistance of the flow rate to the material phase equilibrium with the actual weight of the resistance of the material is called "suspension speed" and "maximum fluidization speed". When the air flow velocity is slightly higher than the air flow velocity, the dried material is carried away by the air flow, and this stage is called the air flow conveying stage.

2. Basic principles of fluidized bed granulation

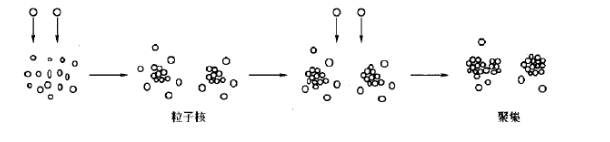

The formation of particles is when the adhesive is uniformly sprayed onto a suspended and loose material, the adhesive droplets moisten the powder in contact and coalesce around them to form particle nuclei. At the same time, the liquid droplets that continue to spray fall on the surface of the particle nuclei to form a bonding bridge, causing the particle nuclei to cross-link and combine with each other, gradually condensing and growing into larger particles.

Schematic diagram of fluidized bed granulation principle

1.3 Fluidized bed drying

During the fluidized bed drying process, the temperature usually undergoes three stages of change: in the first stage of drying, the material temperature is gradually heated from room temperature to the wet bulb temperature of hot air; In the second stage, the material maintains the wet bulb temperature of the hot air unchanged until the moisture content of the material drops to the critical humidity, at which point the material no longer contains free moisture; Subsequently, entering the third stage of temperature rise, the material loses its bound water. When drying, the inlet air temperature should not be too high. The solvent on the surface of the particles evaporates too quickly, blocking the diffusion of the inner layer solvent outward. As a result, a large number of particles with external dry and internal temperature will be generated. If the temperature is too low and the drying time is too long, it will produce many fine powders. The mechanism of modern composite fluidized bed granulation technology

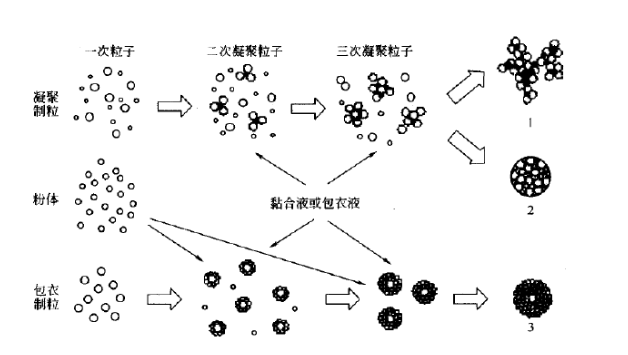

1.2.1 Coagulation granulation The drug powder (primary particle) added to the container is coagulated after the fluidization process and contact with the adhesive liquid of the spray, and gradually grows into the required particles (secondary polymeric particles), which are soft and irregular. Any particles from light amorphous particles to heavy spherical particles can be prepared by selecting appropriate conditions such as agitation, rotation, circulation, spray, fluidization, etc.

1.2.2 Coating granulation takes the primary particle of the powder as the core particle, and its surface is wetted by the snow spraying adhesive liquid and then contacts with other powders. The powder adheres to the particle surface to form powder coated particles. The surface of the coated particles contacts with the spray liquid and powder again, and the spherical particles required for the gradual growth of layers of coated powder.

顆粒生產過程的示意圖

1-Light particles, amorphous 2-heavy particles, spherical 3-coated particles, spherical